Manufacturing Capabilities

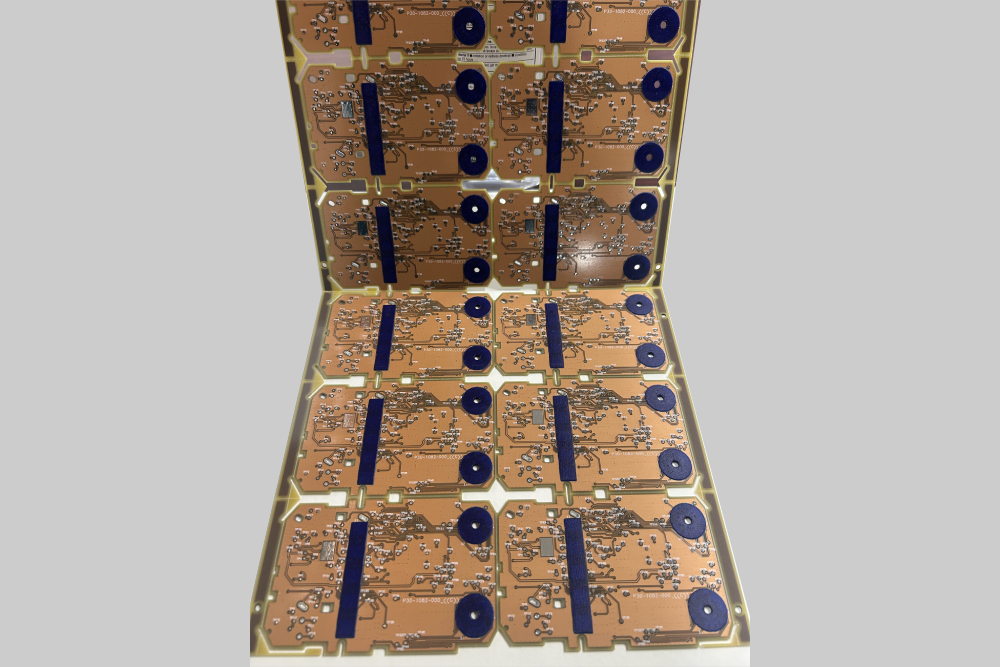

PCB Manufacturing and Finishing Capabilities

At UE, our PCB manufacturing and finishing capabilities meet today’s electronics industry’s high standards and diverse requirements. Our advanced manufacturing processes and finishing techniques ensure that each PCB we produce is of the highest quality and ready to perform reliably in even the most demanding applications.

Advanced Manufacturing Processes

Our state-of-the-art manufacturing facility is equipped with the latest technology to produce PCBs with precision and efficiency. Key features of our manufacturing capabilities include:

- High-Layer Count Boards: We can manufacture multilayer boards with up to 20 layers, allowing for complex circuitry and enhanced functionality.

- Fine Line and Space Resolution: Our capabilities include 4/4 mil lines and spaces, ensuring high-density designs with precise trace width and spacing.

- Blind, Buried, and Stacked Vias: to maximize board real estate and improve electrical performance.

- Sequential Lamination: Our sequential lamination process allows for creating complex, multi-step boards that meet specific design requirements.

Material Expertise

We work with a wide range of materials to provide the best solutions for your specific needs. Our expertise includes:

- High-Frequency Materials: We use materials like Teflon to support high-frequency applications.

- Thermal Management Solutions: We incorporate materials like Thermoset, Polyimide, and metal core options to effectively manage heat dissipation.

- Hybrid Material Circuits: Our capabilities include manufacturing circuits that combine different materials to achieve optimal performance for various applications.

Finishing Capabilities

Our finishing capabilities ensure that each PCB meets your exact specifications and performs reliably. We offer a variety of surface finish options to suit different applications:

- Hot Air Solder Level (HASL) and Lead-Free HASL: Providing a durable and reliable solderable finish.

- Organic Surface Preservative (OSP): Offering a flat, lead-free finish ideal for fine-pitch components.

- Electroless Nickel Immersion Gold (ENIG): Providing a uniform, corrosion-resistant finish for high-reliability applications.

- Immersion Silver and Immersion Tin: Offering excellent solderability and flatness for high-frequency applications.

- Electrolytic Hard and Soft Gold: Providing a high-performance finish for connectors and contact points.

- Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG): Providing a uniform, corrosion-resistant finish for high-reliability wire bondable applications.

Quality and Compliance

Our commitment to quality is evident in our stringent manufacturing processes and adherence to industry standards:

- ISO 9001:2015 QMS Certification: Ensuring robust quality management and continuous improvement.

- IPC Class 2 and 3 Compliance: Meeting high-reliability standards for various applications.

- ITAR Registered and Compliant: Providing secure and compliant manufacturing for defense and aerospace industries.

- UL Certification: Ensuring safety and reliability in all our PCB products.

Customized Solutions

At UE, we understand that each project has unique requirements. Our team works closely with you to develop customized manufacturing solutions that meet your specific needs. From rapid prototyping to high-volume production, we provide flexible and scalable manufacturing capabilities that ensure your project’s success.